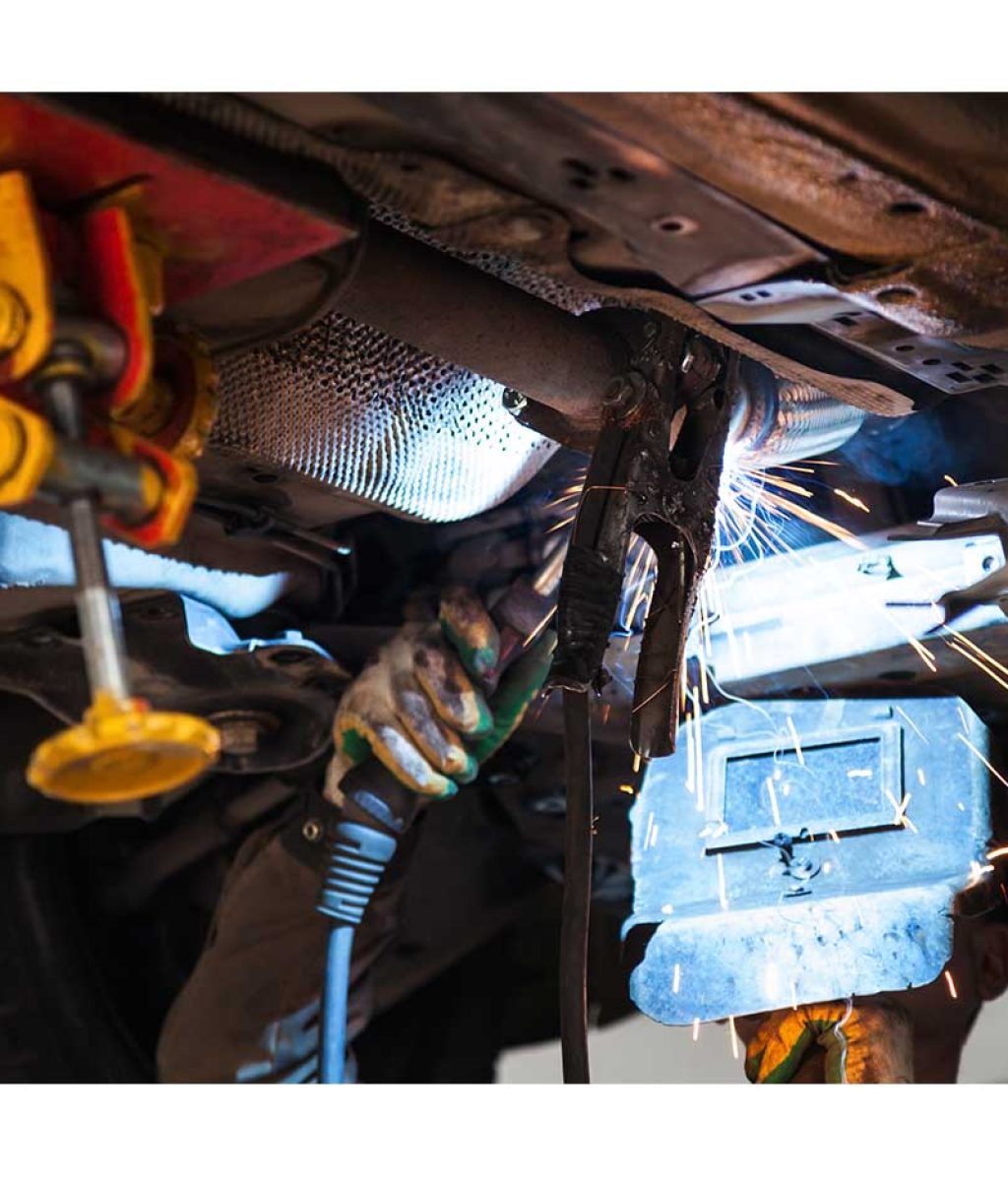

Total Exhaust Support

The silencer is the part of the exhaust that usually needs attention first, as it is the furthest away from the engine and is the most likely to be corroded by moisture. This is because these parts remain relatively cold and give exhaust gases a chance to condense and form pools of corrosive acid inside the system. You’ll know that you have a problem with your silencer because your exhaust starts making a loud roaring noise.

Other noises could indicates a crack in the exhaust manifold, exhaust pipe or a leaking gasket. A blowing noise could mean a blockage in the exhaust system.

Rattling under the car it could mean that the exhaust system has become misaligned. If you hear a loud metallic vibration, something is touching the exhaust pipe or that a clamp, support bracket or mounting is loose. Hangers and brackets hold your exhaust in place. If these become corroded, fractured or fail, it can cause extra stress to the exhaust housing which can also lead to premature exhaust failure.

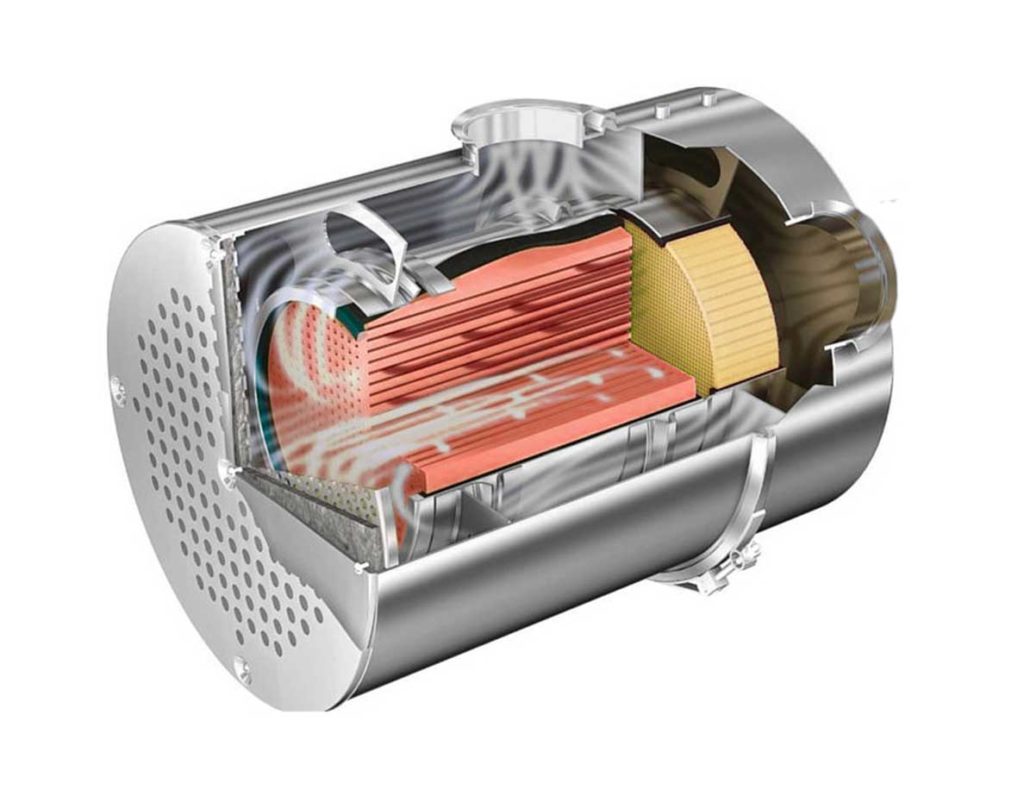

Catalytic Converter

Your exhaust produces harmful emissions of hydrocarbons, carbon monoxide and nitrogen oxides that are damaging to the atmosphere if released into the air.

A catalytic converter substantially reduces the amount of harmful pollutants by taking these gases and converting them into water vapour and less harmful gases via a series of chemical reactions. All petrol cars manufactured since 1993 must have a catalytic converter fitted to the exhaust

Catalytic Mechanism

The catalytic converter includes a core of ceramics perforated with pores that measure less than 1mm. The pores are coated with powdered catalysts that contain metals such as platinum, palladium and rhodium. The pores are close to the engine they heat up and the chemical structure of the exhaust gases passing though it changes so that harmful gases that cause smog are removed and converted into nitrogen and oxygen.

Carbon monoxide and hydrocarbons are broken down and converted into carbon dioxide and water. Catalytic converters are so efficient that the difference in emission readings for cars with converters and those without are considerable. Catalytic converters have a good life expectancy, but still need to be checked periodically for internal and external damage.

Catalytic Problems

Catalytic converter issues can lead to increased exhaust emissions and a decrease in engine performance. Most issues stem from temperature changes in the exhaust system. Excessive unburnt fuel in the exhaust can cause the catalyst to reach extremely high temperatures which can cause damage to the fine catalyst material. As a result, the catalytic converter becomes less effective, less chemical conversions take place and the exhaust output contains more harmful gases.

Similarly, rapid cooling of the catalytic converter, such as by being submerged in water, can cause the internal honeycomb structure to break apart and obstruct the exit to the exhaust pipe. If the catalytic converter becomes plugged, engine efficiency will decrease noticeably.

If you are at all concerned about the performance of your catalytic converter, call into Wilinsons for a free exhaust check

Lambda Sensor and ECU

Another device that helps to reduce carbon emissions is the oxygen or lambda sensor. This monitors the percentage of oxygen present in exhaust gases and sends information to the engine management system or electronic control unit (ECU).

The ECU utilises information obtained from the oxygen sensor and constantly adjusts the air/fuel mixture so that the cleanest and most efficient combustion is achieved under all operating conditions. The oxygen sensor, catalytic converter and ECU all work together to help to achieve the lowest possible output of dangerous and polluting gases.

A failed catalytic converter can be due to a fault in the engine management system or lambda sensor. Our trained exhaust technicians will perform a full inspection of your exhaust system and, by using the latest specialist diagnostic equipment help to identify the cause of the problem to prevent further damage.

Diesel Particulate Filters

Unlike petrol engines, the compression-ignition combustion process involved with powering diesel engines results in the creation of a sooty by-product. Invisible particles contained within this soot can cause significant health and environmental problems if they leave the car as untreated exhaust fumes.

The job of a diesel particulate filter is to trap this soot, and therefore any harmful particles, and prevent them from being pumped out into the atmosphere in the form of the tell-tale smokey black exhaust fumes associated with older diesel vehicles.

The inside of a DPF is usually made up of a highly porous silicon carbide honeycomb. When the unfiltered diesel exhaust fumes flow through a DPF’s channels, the porous walls of this catalytic honeycomb structure traps solid harmful particles and allows the filtered gaseous components of the exhaust to escape in vapour form.

While this process does prevent the vast majority of harmful particles from being released into the atmosphere, the soot itself forms a ‘cake’ layer inside the filter. An excess of this cake layer can lead to blockages when the diesel particulate filter is full, and this can cause potential breakdowns.

DPF Regeneration

To prevent a blockage from occurring, it is essential that your DPF is kept as clean as possible. In order to do this, excess soot stored inside the filter needs to be burned at a high enough temperature to turn into finer ash particles which can then be expelled from the system. This self-cleaning process is known as ‘regeneration’. If this process is interrupted and the DPF is not able to regenerate, faults can occur with the exhaust system.

There are two types of regeneration depending on the system fitted by the manufacturer: active and passive. Active regeneration occurs when extra fuel is automatically injected by the car’s Electronic Control Unit (ECU). This acts to raise the temperature of the exhaust produced by the car, which in turn burns off the excess soot stored inside the DPF. Passive regeneration, on the other hand, occurs at higher speeds when an engine is running at higher revs. Most car manufacturers recommend driving at a consistent speed of over 40mph for a period of more than 30 minutes every few hundred miles to help prevent any DPF blockages. Regular motorway drivers will do this without even realising.

The regeneration process always leaves a small amount of ash residue in the filter which builds up over time and gradually blocks the pours in the walls of the DPF, This means it has to be replaced approximately every 50,000 – 80,000 miles.

DPF Service and Cleaning

DPFs can be professionally cleaned, however this requires removal of the unit and specialist equipment to assess and test after cleaning to ensure it is successful. Cleaning of this type is typically 90-95% effective, compared to a replacement unit.

Some vehicles rely on a fuel treatment known as EOLYS, which is injected into the fuel tank and lowers the temperature needed for regeneration to happen – this fluid reservoir needs refilling (or replacing) .

AdBlue™ is another fluid that is common on diesel vehicles, but this does not directly impact the DPF – however it is important to keep that topped up to prevent other issues.

If your DPF warning light appears and is overlooked, this will usually be followed by symptoms such as a loss of power, poor fuel economy, cooling fans running more than usual and the automatic stop-start system not working in your vehicle